Since the company has made many achievements in research and development in the past two years, it has successively developed products such as TSE 75 and TSE 78 high-end twin-screw food extruders, as well as three-screw food extruders and two-color food extruders. In terms of marketing, we have allocated more energy to other products, and we have not updated the technical trends of our edible rice straw production equipment for a long time. In fact, our rice straw production equipment has been constantly updated and iterated, and we have always been at the forefront of this field. Until I saw a merchant stealing pictures of our edible rice straws for false promotion on a Purchase platform, I had to proclaim this infringement on multiple platforms. The picture below is a stolen picture of our company's product displayed by this merchant in its online store.

Let me report to you the current technical status of our edible tableware production equipment:

At present, the diameter range of the edible rice straws produced by our equipment is 3-14mm (the theoretical production range is larger than this range). In addition, edible tableware such as spoons, knives, forks, etc. can be produced too; after a lot of experiments, according to the straw set the optimal wall thickness for the purpose (too thin will easily break, too thick will waste raw materials).

Edible rice straw sample display:

On the premise of ensuring that the straw is environmentally friendly and edible, the color can be almost as desired.

Application of edible straws:

Protect the environment, start with a straw! After drinking the milk tea, eat the straw too!

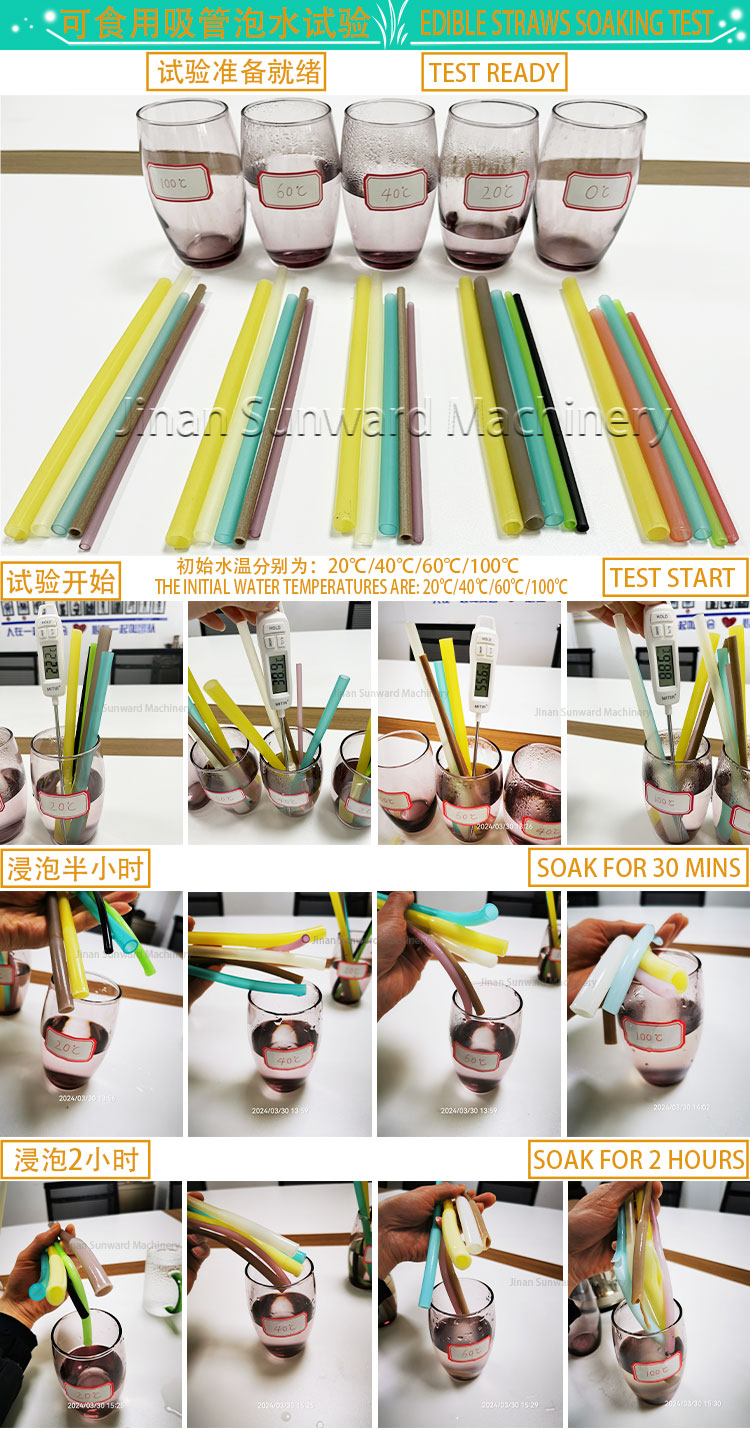

The test results of our edible-grade straws soaked in different temperatures of water:

According to test data, our edible-grade straws can still be used after being soaked in water with an initial temperature below 60 degrees Celsius for 2 hours. Because it is of edible grade, no substances harmful to the human body can be added. This type of straw also fully complies with the import standards of the European Union and other countries. If it only meets the environmentally friendly and degradable requirements, then an environmentally friendly grade straw that meets this requirement can maintain a service life of more than 48 hours in beverages with a water temperature below 60 degrees Celsius.

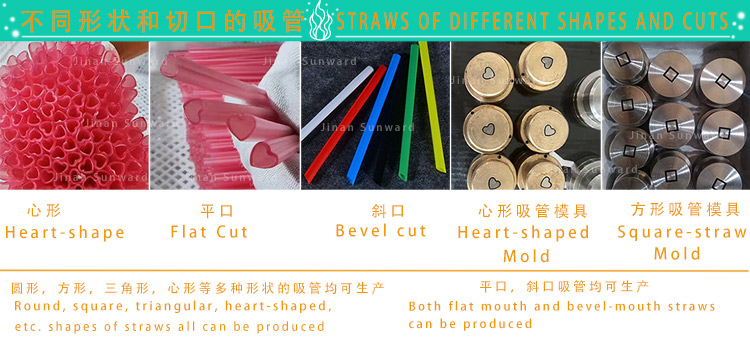

Straw shape and cut-mouth type

The main shape of most straws is round straws. Of course, other shapes can also be made, such as heart-shaped straws, square straws, and triangular straws. This technical difficulty is not high and can basically be achieved by using different molds. In fact, it is still difficult to make beveled edible straws without significantly increasing the cost of equipment and production time (it is easier to make bevel cuts on short tubes, and a macaroni cutting machine can be used). Usually, plastic straws are made into beveled straws by cutting the straws into a certain length and then making bevel cuts, which is equivalent to adding another process. According to the characteristics of the edible straw production process, our company has specially developed a cutting machine for the one-time forming of beveled mouth straws, which not only reduces the cost of the production line, but also saves labor and time costs.

In addition, many aspects such as the formula of edible straws, the extrusion process and drying process of edible straws, and even seemingly inconspicuous details affect the quality of the straws and determine whether competitive of the products produced by the edible drinking straw company. For example, in the drying process, common problems include bending of the straw after drying, bubbles in the wall of the straw, cracking of the straw, and incomplete drying. Other common problems include rough straw bodies, uneven straw cuts, and straws not resistant to soaking.

Project cases

At present, our edible straw production equipment has a large number of users at home and abroad. We have rich experience in R&D, production and after-sales service, as well as a large amount of product-related data, and hold a number of invention patents to provide more mature and reliable products and Laying a solid foundation for better customer service. The following are some customer cases of our edible straw production equipment

Copyright © Jinan Sunward Machinery Co., Ltd. 2014 All rights reserved

Tel:0086-531-67877802

Tel:0086-531-67877802  Cel:+8618865912025(Whatapp)

Cel:+8618865912025(Whatapp)  E-mail:carol@cnsunward.com

E-mail:carol@cnsunward.com

①Factory Address --Xiaoluzhuang Industrial Park, Jinan City, China

②Room 1304,Shanxin Mansion,Qizhou Road,Huaiyin District,Jinan city,Shandong Province,China